Electromechanical servo press

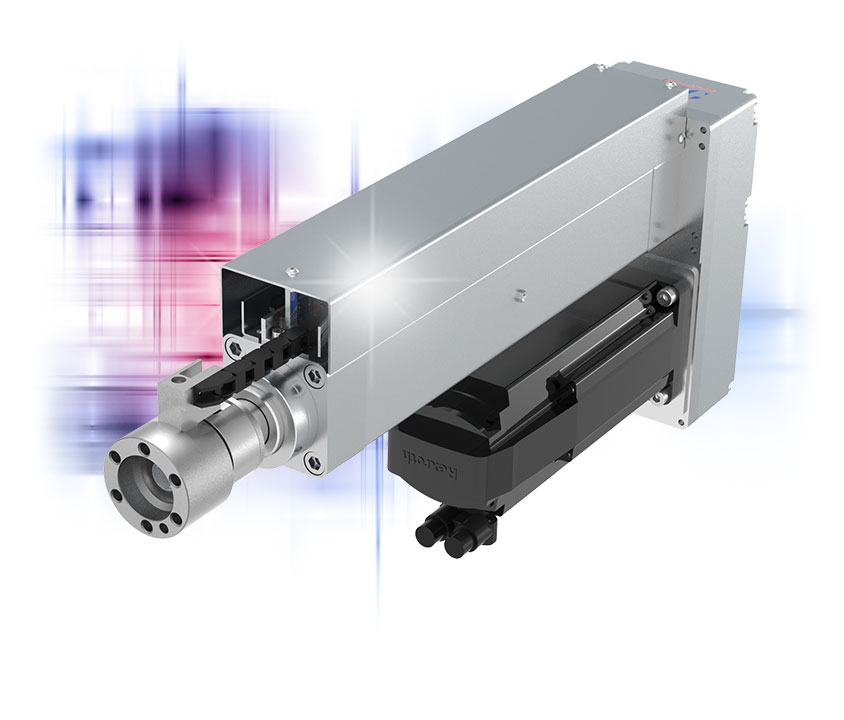

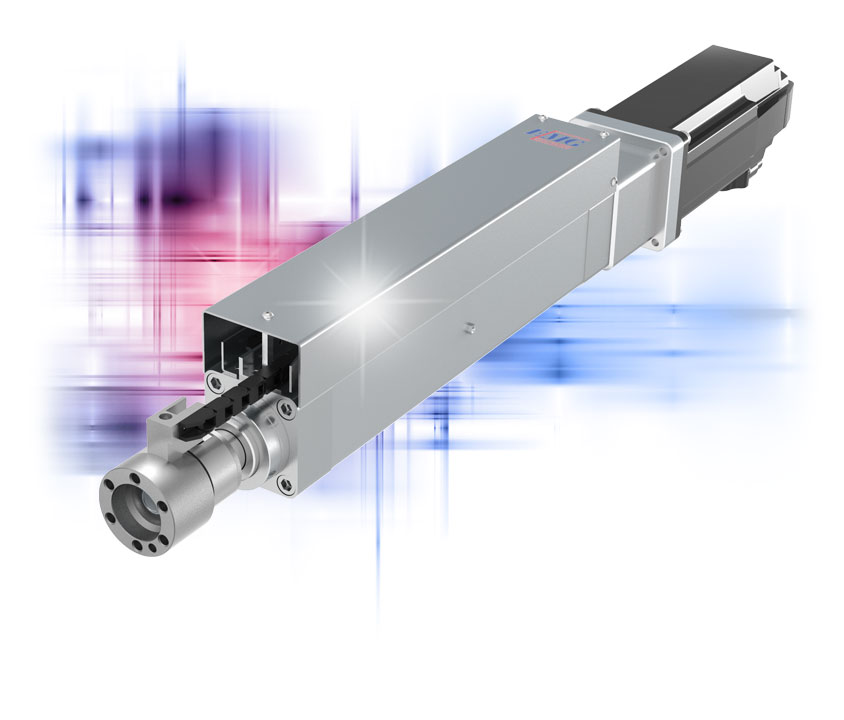

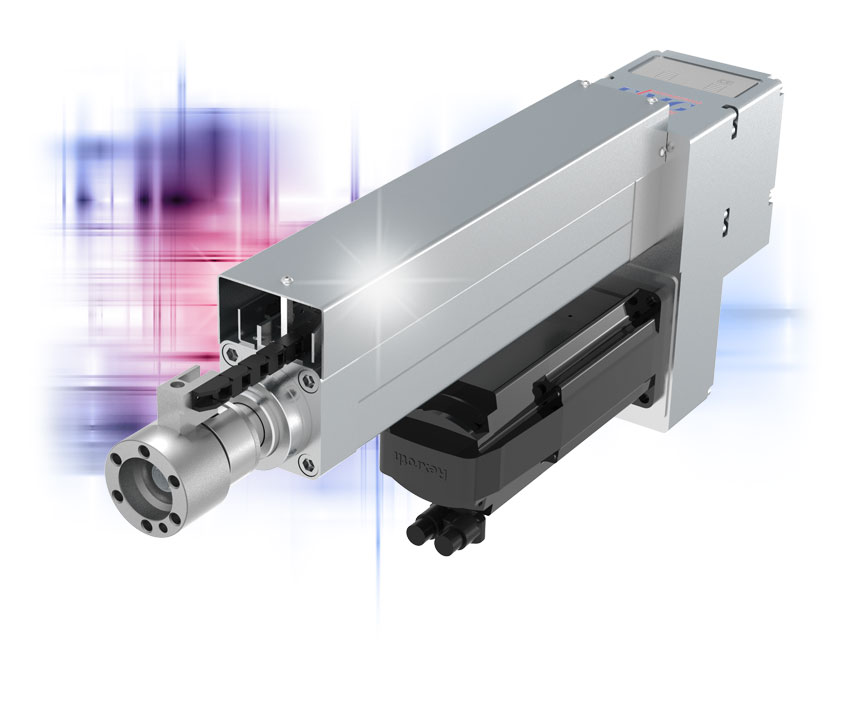

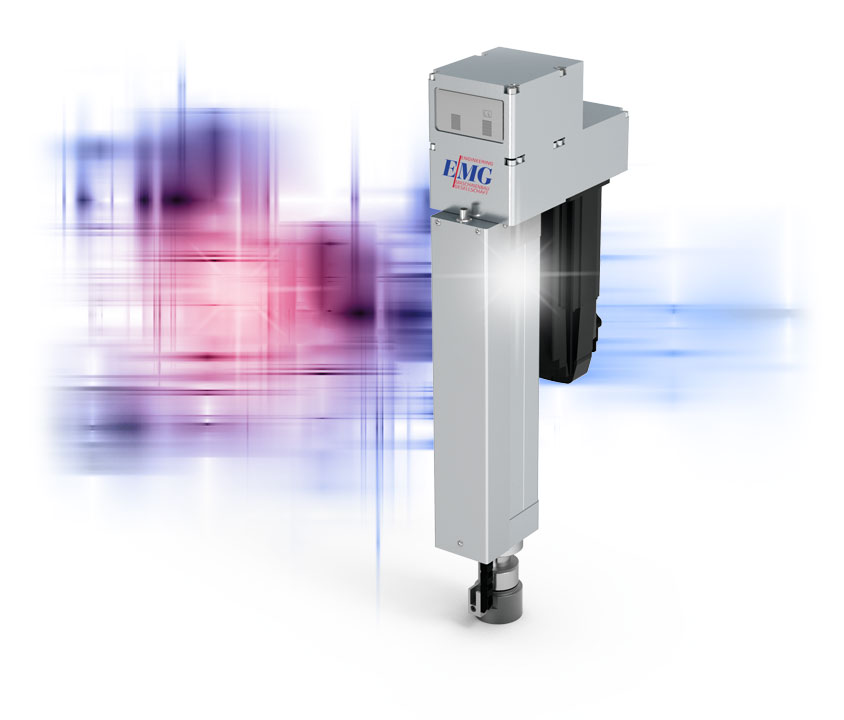

EMSP 6 250 AM SB

FORCE RANGE 6 KN, STROKE 250 mm

- System: Electromechanical servo press

- Short name: EMSP 6-250-AM-SB-XX

- Pressing force: 6 kN

- Effective stroke: 250 mm

- Max. traverse speed: 250 mm/s

- Motor attachment: Angled motor

- Safety brake: SB (with safety brake)

- Generation: XX (latest product generation)

- System accuracy:

Displacement repeatability 0,01 mm

Force measurement < 1% f.s.

Item no. 18369

- Robust mechanics based on proven ball screw spindles

- Aluminium housing, anodised

- Mechanics with additional safety brake

- Redundant, secure braking and holding system

- Flange mounting

- Guide of the screw drive secured against rotation

- Standardised tool holder

- Piezoelectric force transducer integrated in the tool holder

- Servo motor with absolute encoder and holding brake

- Control unit with firmware and integrated safety technology

- Standardised sequence program for force-displacement regulated control of the servo press contained in the controller;

Parametrisation and evaluation via EMG system software for the PC - Drive-based controller and monitoring of process parameters directly in the servo controller

- Measuring direction: designed for push operation (pull operation optional)

- Charge amplifier with two independently variable force measuring ranges

- 2nd measuring range can be used for higher resolution of a smaller force measuring range

- Motor, encoder and force transducer connection on connector

- IndraDrive drive system from Bosch Rexroth

- Speed guide values for joining functions:

Positioning max: 250 mm/s

Latch-on (first contact): 2 bis 5 mm/s

Joining to position: 2 bis 50 mm/s

Joining on block: 2 bis 50 mm/s

Holding time of the nominal force: min. 5 sec.

- Press mechanics with servo motor

- Servo controller with control unit

- Mains filter

- Charge amplifier

- Control unit for safety brake

| Basic Module | EMSP 6 | |

|---|---|---|

| Nominal force | [kN] | 6 |

| Traverse speed | [mm/s] | 250 |

| Standard stroke | [mm] | 250 |

| Spindle type | Ball screw drive | |

| Motor attachment | Angled motor (short design) | |

| Motor equipment | With electric holding brake and absolute encoder as standard | |

| Mounting method of the servo press | Flange mounting |

| FORCE MEASUREMENT | ||

|---|---|---|

| Force sensor | Piezoelectric Quartz force transducer |

|

| Force measuring range* | [kN] | 0 – 6 |

| System accuracy | < 1% of the nominal value |

* Two force measuring ranges individually adjustable and automatically switchable to increase force accuracy.

| DISPLACEMENT MEASUREMENT | ||

|---|---|---|

| Displacement encoder | Absolute encoder | |

| Displacement repeatability | [mm] | < 0,01 |

| SPEED GUIDELINES | ||

|---|---|---|

| Positioning | [mm/s] | max. 250 |

| Latching on | [mm/s] | approx. 2 - 5 |

| Joining to position | [mm/s] | approx. 2 - 50 |

| Joining on block | [mm/s] | approx. 2 - 50 |

| Holding time | Tmin = 5 sec. at Fmax 6 kN | |

| Power supply | ||

|---|---|---|

| Power supply | 400V - 3~ - 50/60 Hz | |

| Control voltage | 24V DC |

EMG system software

Powerful, Windows-based QA software for up to 12 servo presses per PC.

Programming, visualising, monitoring and documenting joining processes.

Item no. 14162

Standard EMSP 6 cable harness

Motor, encoder and force transducer cables

Length: 10m

Item no. 14650

FURTHER OPTIONS

EMSP 6 Power Electronics

Components for safety control system, assembly, wiring and commissioning of power electronics

Item no. 14651

Profinet interface

For coupling the servo press controller to a master, e.g. to Siemens S7

Item no. 17888

Displacement transducer interface

Encoder interface for connecting an additional displacement transducer.

Item no. 14408

EMG industrial PC evaluation system

Complete force-displacement monitoring

consisting of PC hardware and QA software

designed for programming and monitoring a servo press

Item no. 14166

Uninterruptible power supply

In connection with EMG industrial PC evaluation system

Item no. 14168

Setup for remote maintenance

With the aid of the remote maintenance software the PC can be operated from outside

Item no. 14165

YOUR CONTACT PERSON

Dipl.-Ing. (FH)

CHRISTIAN HILSMANN

will be happy to answer your questions – by e-mail or on the phone

c.hilsmann@emg-engineering.de

+49 (0) 29 51 / 93 883 – 13