MACHINE PARK

STATE-OF-THE-ART TECHNOLOGY OVER 1600M²

LATEST TECHNOLOGY

OF THE HIGHEST QUALITY

CNC machining centres

- 5-axis high-performance machining centre

Hedelius ACURA 65 EL with integrated rotary swivel table unit and 65-multiple tool magazine.

Main spindle upgrade to 18,000 min-1

Spindle power: 35.0 kW/142 Nm

Traverse paths:

X-axis 700 mm

Y-axis 650/465 mm

Z-axis 600 mm

Incl. handling system pallet storage Indumatik

Automatic system for loading and unloading workpiece carriers for 12 pallets of size 400 x 400 mm

Laser tool control system for non-contact tool measurement and tool damage detection

Collision monitoring

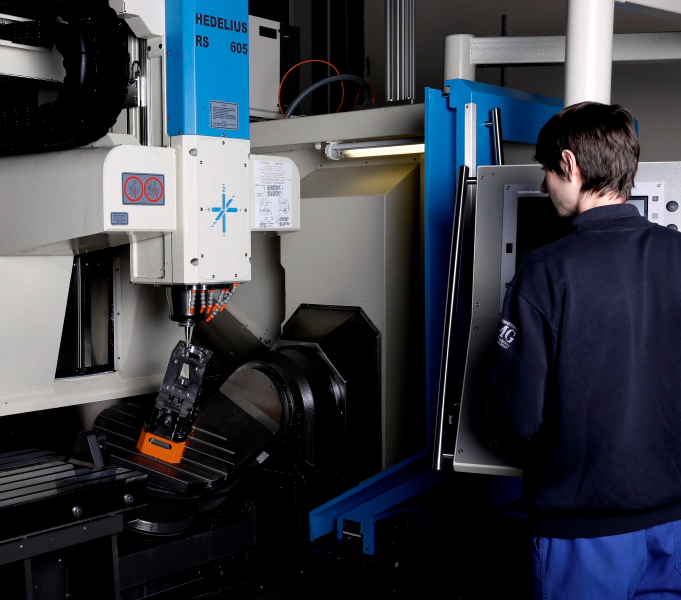

Year of manufacture 2017 - 5-axis machining centre

Hedelius RotaSwing 605 K20 with integrated rotary

swivel table unit and 30-multiple tool magazine.

Main spindle upgrade to 12,000 min-1

Spindle power 22.00 kW/111 Nm

Traverse paths:

X-axis 1330/620 mm, long operation 2000 mm, swing operation: 950/620 mm.

Y-axis 650/385 mm

Z-axis 520 mm

Incl. work area separating wall for swing operation

Tool damage detection

3D infrared touch probe

Toolsetter 2D touch probe for measuring and checking the tools

Year of manufacture 2012

CNC lathe

- 2-axis universal lathe

DMG MORI CLX 450 V6 with driven tools, C-axis, Y-axis and counter spindle.

Main spindle 4,000 min-1

Spindle power 17/25.5 kW

12-multiple servo tool revolver with 12 driven tool stations

Direct path measuring system X-,Y-axis

Incl. automatic loading magazine

for short bars, bar capacity D80 mm

Workpiece pick-up device for parts up to D80x200 mm, weight max 4 kg

Parts compartment outside the working area

Turning diameter max. 400 mm

Turning length 800 mm

Year of manufacture 2020 - CNC lathe

Gildemeister CTX 400 S2 with driven tools

main spindle 5.000 min-1

spindle power 21 kW

12-multiple tool revolver

Turning diameter max. 470 mm

turning length 600 mm

Year of manufacture 2001

Measuring equipment

- Measuring arm Faro Prime

6-axis, 2.4m 8 Ft.

Repeatability +/- 0.024 mm (single point accuracy)

Accuracy +/- 0.034 mm (volumetric maximum deviation)

Typical applications

Automotive: tooling, alignment, part inspection.

Metal fabrication: Initial inspection, part verification

Aerospace: alignment, tool and mould certification, part verification.

Includes Faro 3D measurement platform software, for efficient fulfilment of quality assurance and inspection tasks. Perfect for managing repetitive inspection routines.

Year of manufacture 2013

Robot station for testing gripper and handling systems

- Robot model YASKAWA MH50 II

The versatile MH50 II is a flexible, 6-axis, high-speed robot with a max. payload of 50kg and a max. working range of 2061mm. It is particularly suitable for handling, machine tending, processing and distribution applications.

Important technical data:

– Design: articulated arm robot

– 6 electrically driven servo axes with absolutely precise pulse encoders

– max. payload (per arm): 50.0 kg

– max. reach (per arm): 2061 mm

– repeatability: better than +/- 0.07 mm

Year of manufacture 2019

Material preparation

- 2-column high-performance bandsawing machine

BERG & SCHMID SBS 420 VA-I CNC

Cutting diameter round: 420 mm

Cutting diameter square: 420 mm

Cutting diameter flat: 420 x 420 mm

Year of manufacture 2019 - Double mitre band saw

BERG & SCHMID GBS 250 Super AutoCut

Cutting diameter round: 255 mm

Cutting diameter square: 240 mm

Cutting diameter flat: 300 x 180 mm

Year of manufacture 2018 - Underfloor aluminium circular saw

BERG & SCHMID MultiCut 401 HA

Cutting diameter round: 110 mm

Cutting diameter square: 100 mm

Cutting diameter flat: 200 x 60 mm

Year of manufacture 2019

Conventional machines

- Various drilling, turning and milling machines

Welding process

- Welding of machine frames, small series production of assemblies

TIG, MIG, MAG welding - Welding table EcoLine

Demmeler Maschinenbau GmbH

table size: 2400x1200mm

Year of manufacture 2010

GET IN CONTACT WITH US!