Electromechanical servo presses

Structure

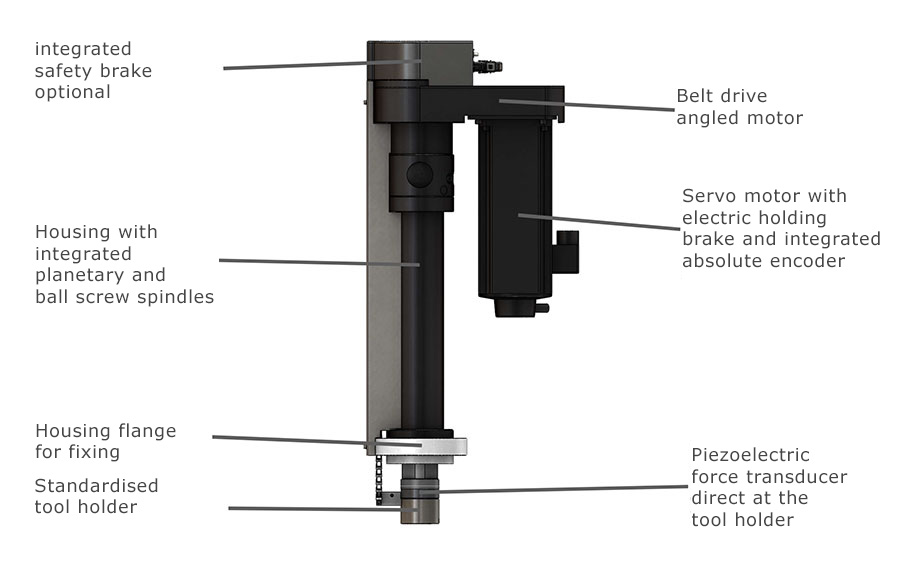

STRUCTURE OF THE ELECTROMECHANICAL SERVO PRESS

The mechanics of the electromechanical servo press are based on proven planetary or ball screw spindles with different diameter and lead combinations, specially adapted to achieve different press-fit forces and speeds.

A screw drive converts a rotary torque into a linear movement with high efficiency. In the process, the piston rod attached to the screw drive nut is retracted and extended. Both the nut and the piston rod are guided in the housing. The interface between piston rod and housing is optimally sealed to prevent the ingress of dirt.

The electromechanical servo press includes an anti-rotation piston rod.

The integrated anti-rotation device is realised by four guide surfaces on the piston rod and a sliding guide in the housing.

Integrated end position buffers protect the mechanics during commissioning.

The electromechanical servo press requires little maintenance. Grease lubrication has the advantage that the screw drives only need to be relubricated after long traverse displacements.

AN EMSP ELECTROMECHANICAL SERVO PRESS CONSISTS OF:

- Mechanics: Housing with integrated planetary or ball screw spindle

- Standardised tool holder

- Force measurement:

– Piezoelectric quartz force transducer directly on the tool holder

– Charge amplifier with two independently variable measuring ranges (control cabinet module) - Servo motor with electric holding brake

- Displacement measurement: absolute encoder in servo motor

Technology

Electromechanical servo presses

Downloads

Your contact person

Dipl.-Ing. (FH)

CHRISTIAN HILSMANN

will be happy to answer your questions – by e-mail or on the phone

c.hilsmann@emg-engineering.de

+49 (0) 29 51 / 93 883 – 13